Industrial accessories compatible with ASI equipment

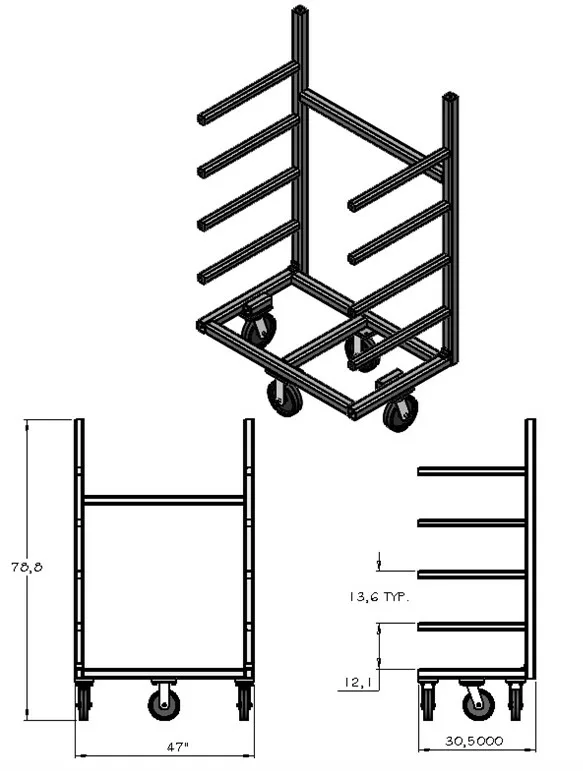

Component cart

- Powder coated finish steel tubing construction

- Cushioned-Load Casters. Rigid with 8″ Diameter 80A Rubber Wheel and Stamped Frame – 600 lbs rated/ea caster

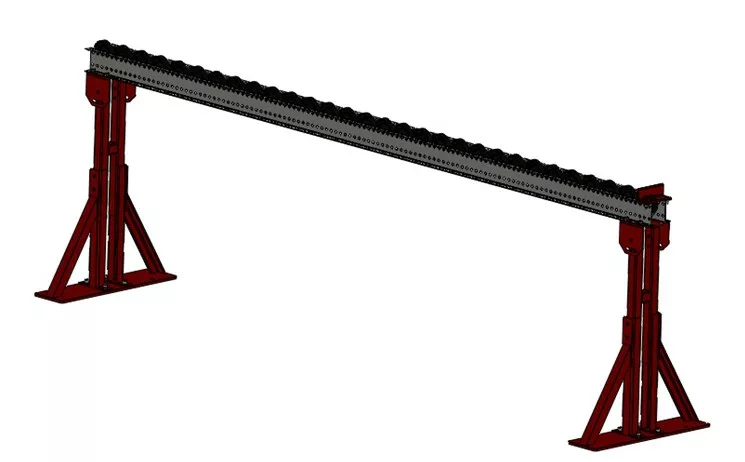

Free standing track rollers

- Used for infeed or outfeed to the saw

- Height adjustable, incline adjustable. With end stops.

- Flexible configuration

- Freestanding (can be moved away easily) or anchored to the floor.

- Overall width: 24-1/4in; overall length: 113in; height adjustable from 28-3/4in to 40-1/2in.

- Compatible:

- asiRS

- BasiC

Live deck – motorized chain conveyor for lumber feed

- Motorized chain conveyor – lumber feed to the saw.

- 15ft wide X 21.5ft long – accepts lumber up to 20ft long

- Heavy duty steel construction – powder coat paint- adjustable legs.

- Remote controls and e-stop, wrap-around safety pull cord e-stop, chain return guards.

- 3HP motor – 480V/3ph/15A. cULUS control panel.

- Compatible:

- MasiK

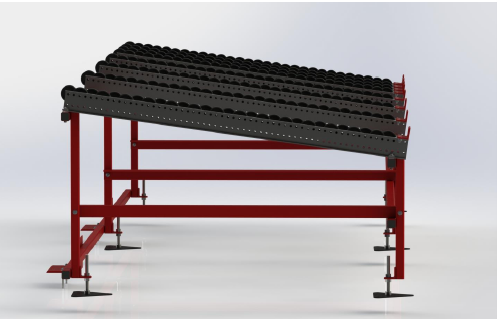

Lot of inclined conveyors for catcher

- Create a buffer zone for the catcher in between the parts being cut and the material handling carts.

- Covers 5 or10 feet in length on the saw exit side.

- Gravity roller conveyor including powder coated steel frame and wood stops.

- Compatible:

- MasiK

Lumber scrap inclined conveyor

- Dimensions: 24in wide X 12ft in length. Approximatively 60in in height at discharge;

- Motorized inclined conveyor connected and controlled by the saw;

- Includes motor & gearbox assembly, belt, wiring and painted steel structure.

- Compatible:

- MasiK

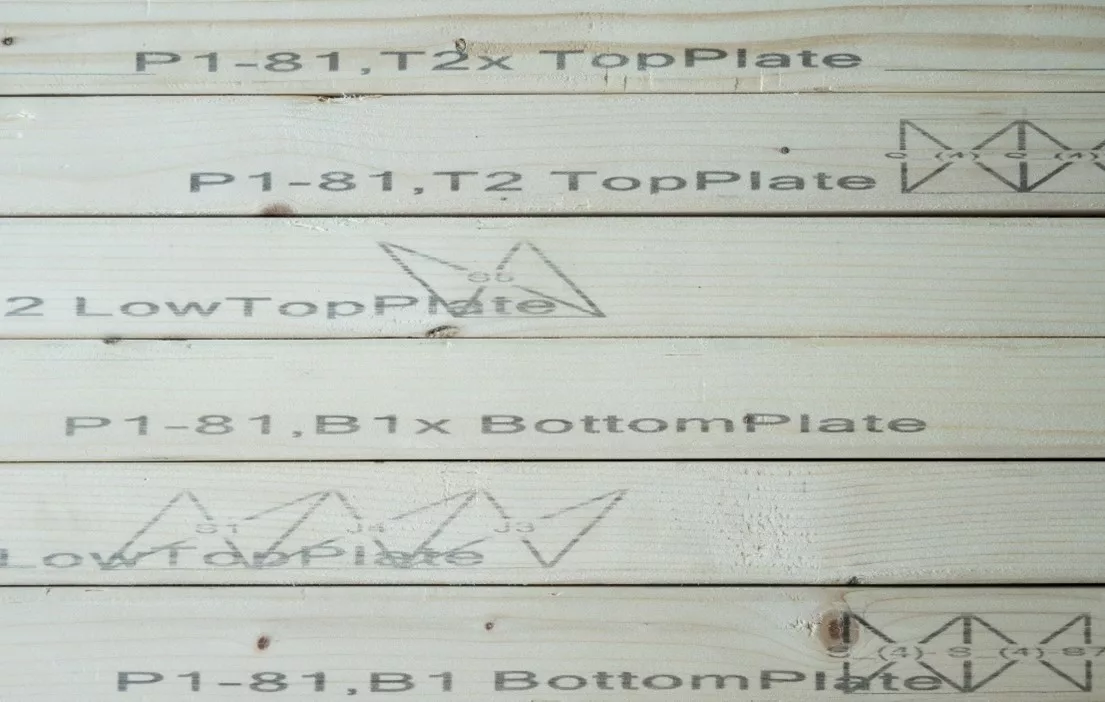

Printing system for marking plates and most printable parts 3 or 4 pens

- Prints on the narrow side of the piece (the 1 ½’’ side)

- Installed near the saw blade

- Allows printing

- one piece at the time with 3 pens

- two pieces at the time with 4 pens

- Easy and fast maintenance, but required daily

- Compatible:

- asiRS

- BasiC

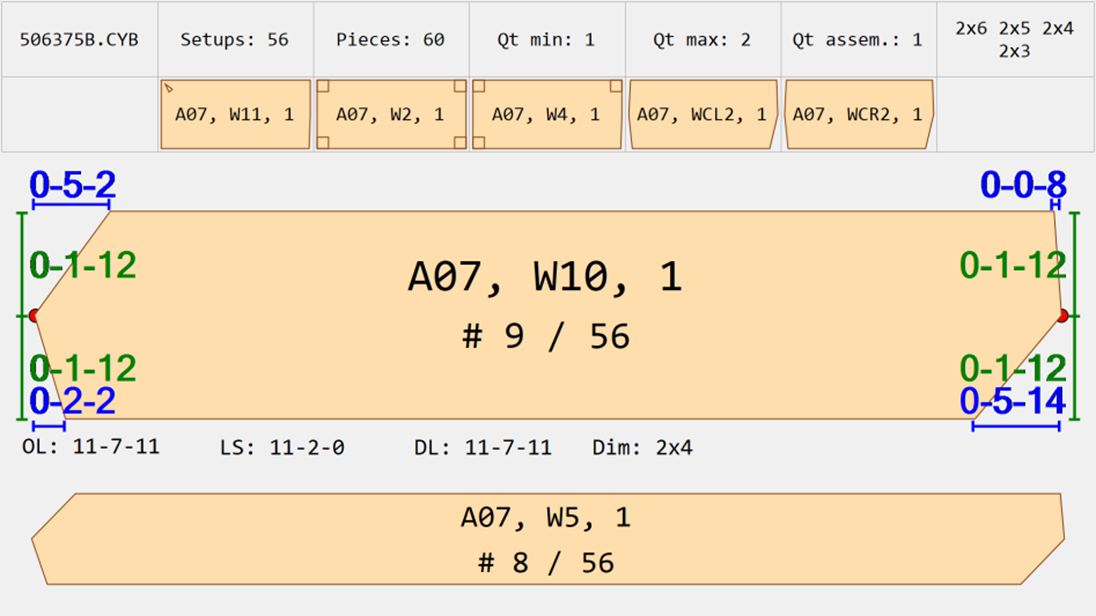

HP2 3-pen printing system

- Prints on the narrow side of the part (the 1-1/2in side). Refer to below sample picture.

- Installed inside the saw.

- Requires the installation of shorter flights on the printer side of the infeed chain.Consumes an extra 5-10 SCFM of compressed air, tubed from the saw existing pneumatic circuit.

- Minimum cutting length increases to:

- 24in in auto or manual for 90deg cuts.

- 36in in auto or manual for angle cuts 20/70-70/20

- Maintenance is quick and easy but required daily.

- Compatible:

- MasiK

Supplementary catcher display monitor

- 24 inches monitor installed on the catcher stationary side.

- Displays in real time: 2D representation of the previous part, of the current part and of the following part. Each part is identified with its lot and name. The current part has a larger image and shows the quantity required to cut. Dimensions in X and Y coordinates are shown to ease quality control of cuts.

- Compatible:

- MasiK