BasiC

RADIAL SAW AUTOMATED

SYSTEM RETROFIT KIT

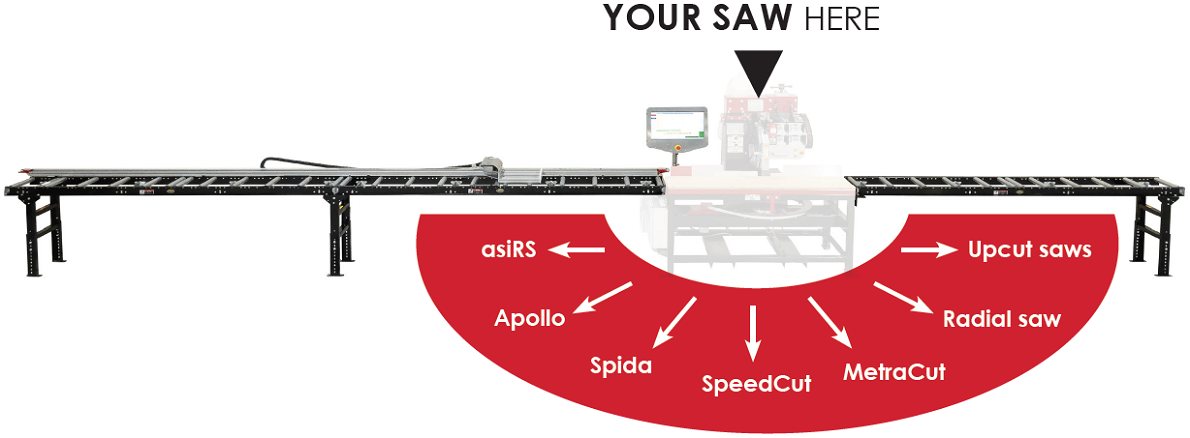

BasiC is a system that automates the length and angle of cut performed on a radial arm saw.

FEATURES

- Automates length and angle cuts or length only

- Fits on your existing saw frame and conveyor system:

- asiRS

- Apollo

- Spida

- SpeedCut

- MetraCut

- Radial saw

- Upcut saws

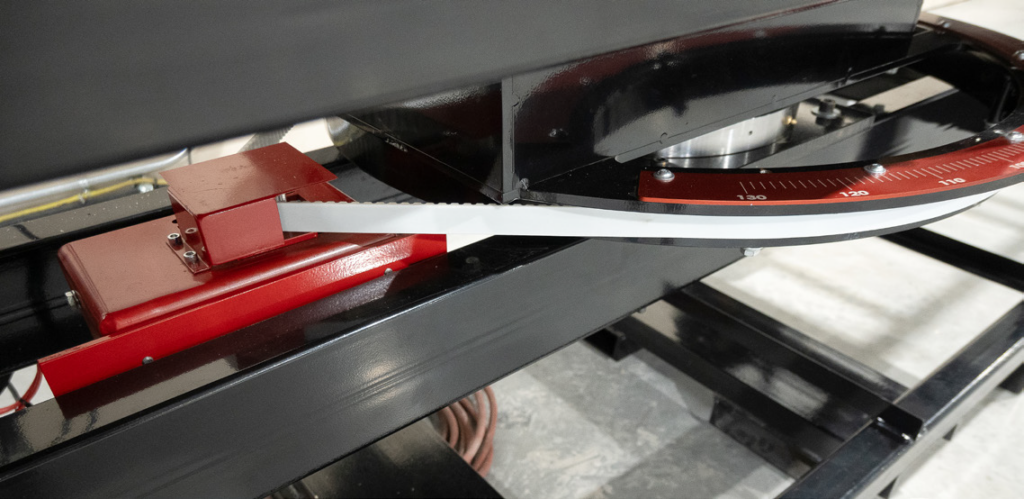

- Steel reinforced polyurethane positioning belt ensures accuracy

- Up to 15°/sec. Angulation

- Angles adjust from 7° to 90° (frame depending)

- > 90° angles done flipping the component

- Length adjust from 0in to 23ft (frame depending)

- Can be connected to your network to upload the cutting lists directly to the computer

- Saw files read: EHX, TRS, Sapphire XML, EZY, CYB, WCD, ASI, BTL, BTLx

- Intuitive multilingual English, French and Spanish HMI

UP TO

66IN/SEC

DISPLACEMENT

SPEED

NO MORE

MANUAL

DATA ENTRY

INCLUDES

- Length and/or angle automation system

- Up to two (2) high resolution, high speed & high torque servo motors for accurate positioning with integrated Schneider-Electric drives.

- 24in Lenovo touchscreen SSD computer with BasiC software and Windows 11 Pro OS, c/w ultra-intuitive human machine interface.

- Easy axis by axis calibration.

- Step by step mode for:

- Diagnostics

- Maintenance

- Cleaning

- cULus approved control panel

- Lifetime access to software updates

SAFETY FEATURES

- Schneider-Electric ILA2 built-in category 1 dual contact

- Safe Torque Off

- Independently adjustable displacement speed and acceleration:

- Moving towards the blade vs away from the blade

- Positive vs negative angulation motion

- Sharp angles warning

OPTIONS

- BasiC L automation for length only

- Plate marker

- BasiC AL automation for Angle and Length

- Trusses + plates

- Printing System for marking wall plates

- 3 or 4 pens options

- Customizable length

- Lot of critical spare parts

- Lot of roller conveyors and supporting stands

- Tempered glass industrial PC upgrade

- Periodic maintenance program

DOCUMENTATION