MasiK Options.

HP* 3-pen printing system.

- Prints on the narrow side of the part (the 1-1/2in side). Refer to below sample picture.

- Installed inside the saw.

- Requires the installation of shorter flights on the printer side of the infeed chain.

- Consumes approximately 5-10 SCFM of compressed air, tubed from the saw existing pneumatic circuit.

- Minimum cutting length increases to:

- 24in in auto or manual for 90deg cuts.

- 36in in auto or manual for angle cuts 20/70-70/20

- Maintenance is quick and easy but required daily.

Some restrictions apply.

Lot of electrical spare parts.

- ILM Servomotor ILM (1X)

- lot of cables (Sercos, Hybrid et Ethernet) (6X)

- fuses (2X)

- part counter sensor (1X)

- …

Detailed list available upon request.

Lot of mechanical spare parts.

- One 7.5 HP motor

- 20L of MXEP lubricant

- one spare 20in blade

- sprockets

- chain link

- couplings

- hold-down slides

- springs

- infeed flights

- gears

- saw blade brake cylinder

- blade brake pad

- brass nuts

- pneumatic hose and fittings

- …

A total of 94 items. Detailed list available upon request.

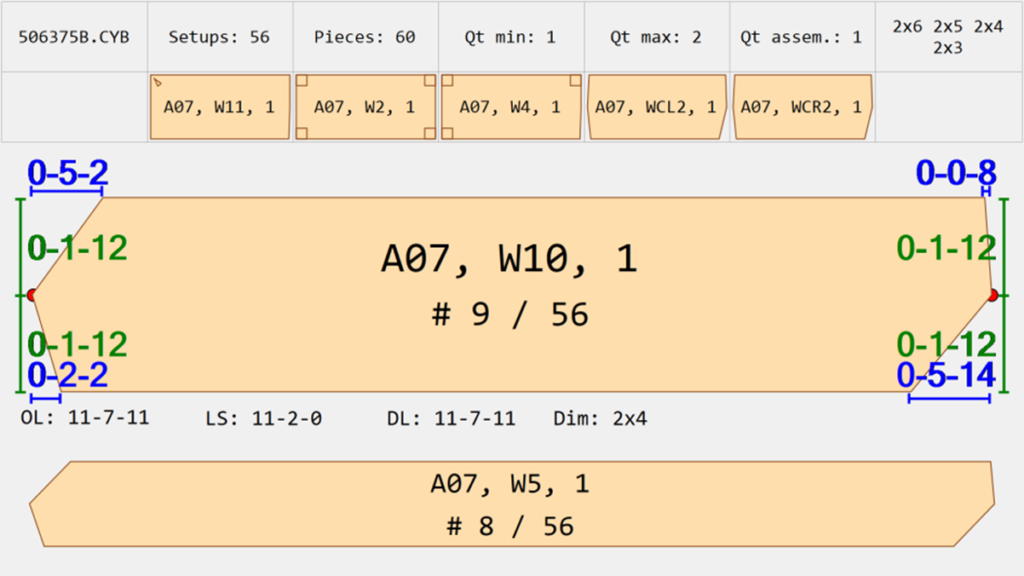

Supplementary catcher display monitor

- 21 inches monitor installed on the catcher stationary side.

- Displays in real time :

- 2D representation of the previous part, of the current part and of the following part.

- Each part is identified with its lot and name.

- The current part has a larger image and shows the quantity required to cut.

- Dimensions in X and Y coordinates are shown to ease quality control of cuts.

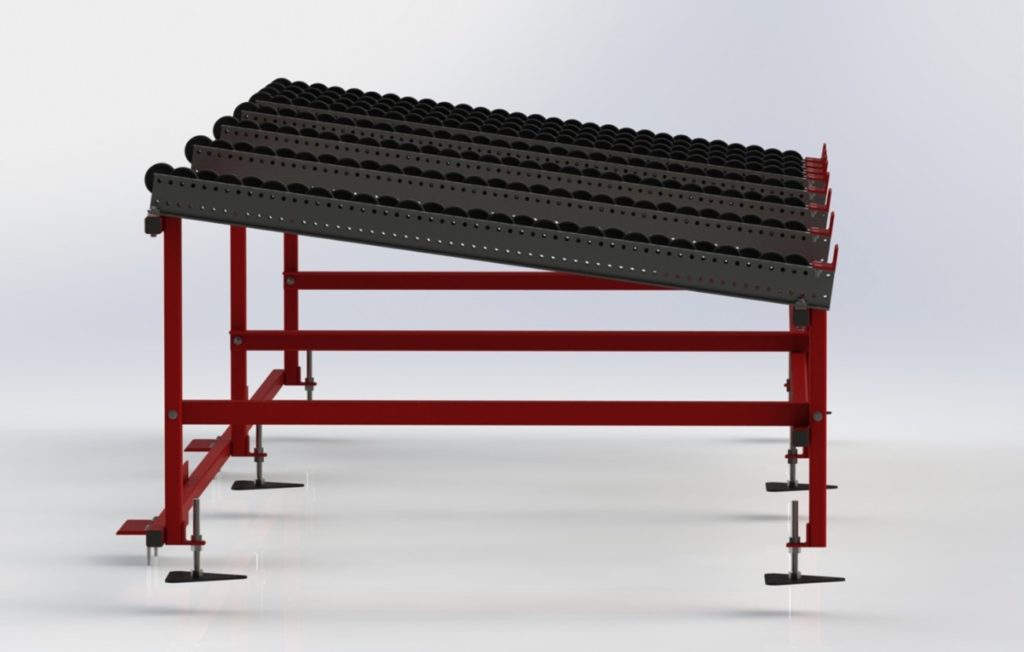

Lumber scrap inclined conveyor

- Dimensions: 24in wide X 12ft in length. Approximatively 60in in height at discharge.

- Motorized inclined conveyor connected and controlled by the saw.

- Includes motor & gearbox assembly, belt, wiring and painted steel structure.

Lot of inclined conveyors for catcher

- Create a buffer zone for the catcher in between the parts being cut and the material handling carts.

- Covers 5 or 10 feet in length on the saw exit side.

- Gravity roller conveyor including painted steel frame and wood stops.