asi[M]1

WALL EXTRUSION

SYSTEM

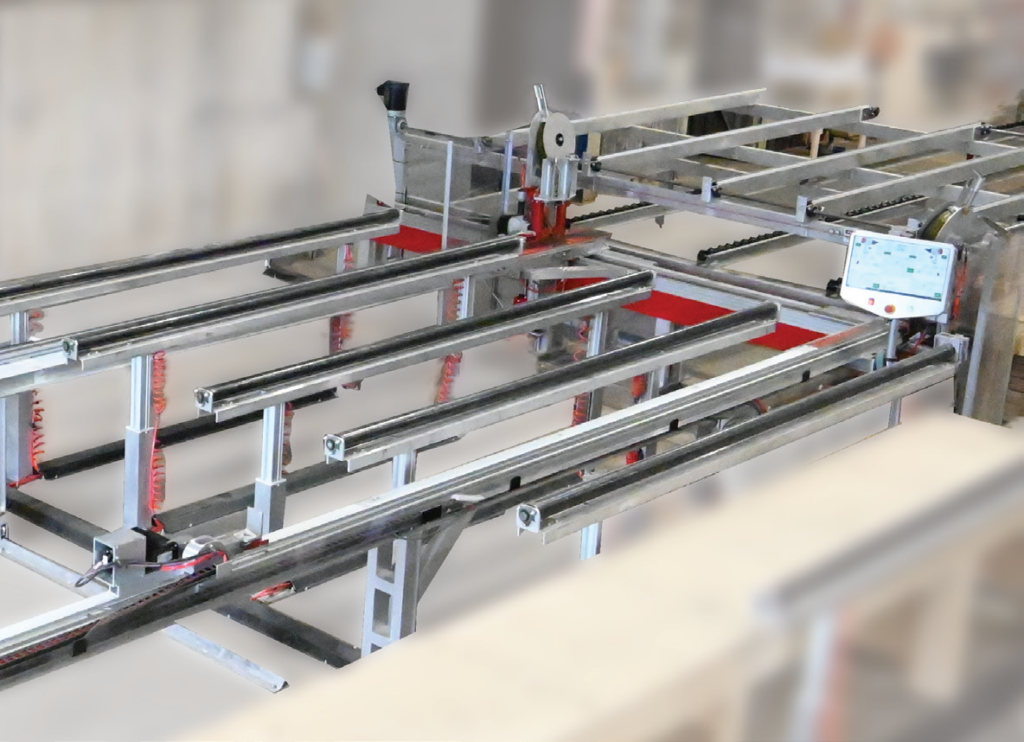

asi[M]1 is a machine that assembles wall panel frames.

FEATURES

- Handles wall frame from 2×3 to 2×8, up to 30ft long

- Wall frame height from 34in to 146-1/2in

- 1 stud every 5 sec. dry cycle

- 1 stud every 12 sec. normalized cycle, w/o noggins

- Configurable studs nailing pattern, height by height

- Up to 3 nails per sec.

- 2000 to 3500 nail coil holder

- Intuitive Multilingual English, French and Spanish HMI

- Wall files read: EHX, Sapphire XML, WCD, ASI, BTL, BTLx

16IN STUDS SPACING

100 TO 240LF

PER HOUR

INCLUDES

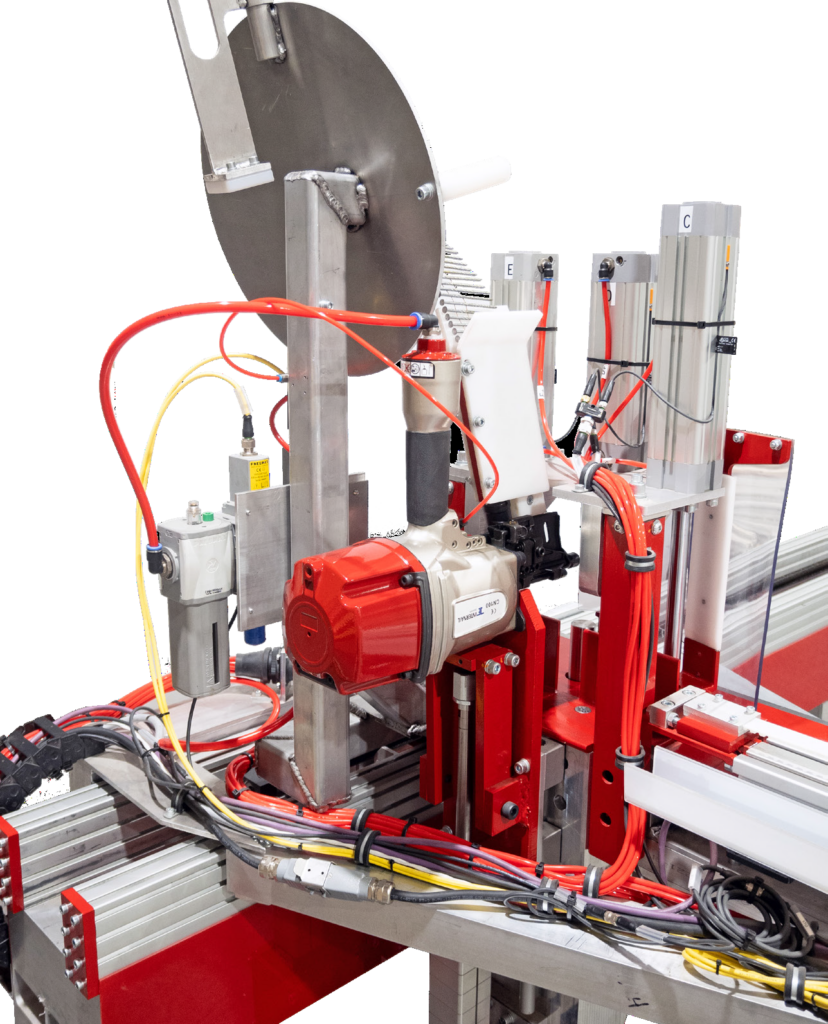

- Automatic nailing system simultaneously nailing top and bottom plates

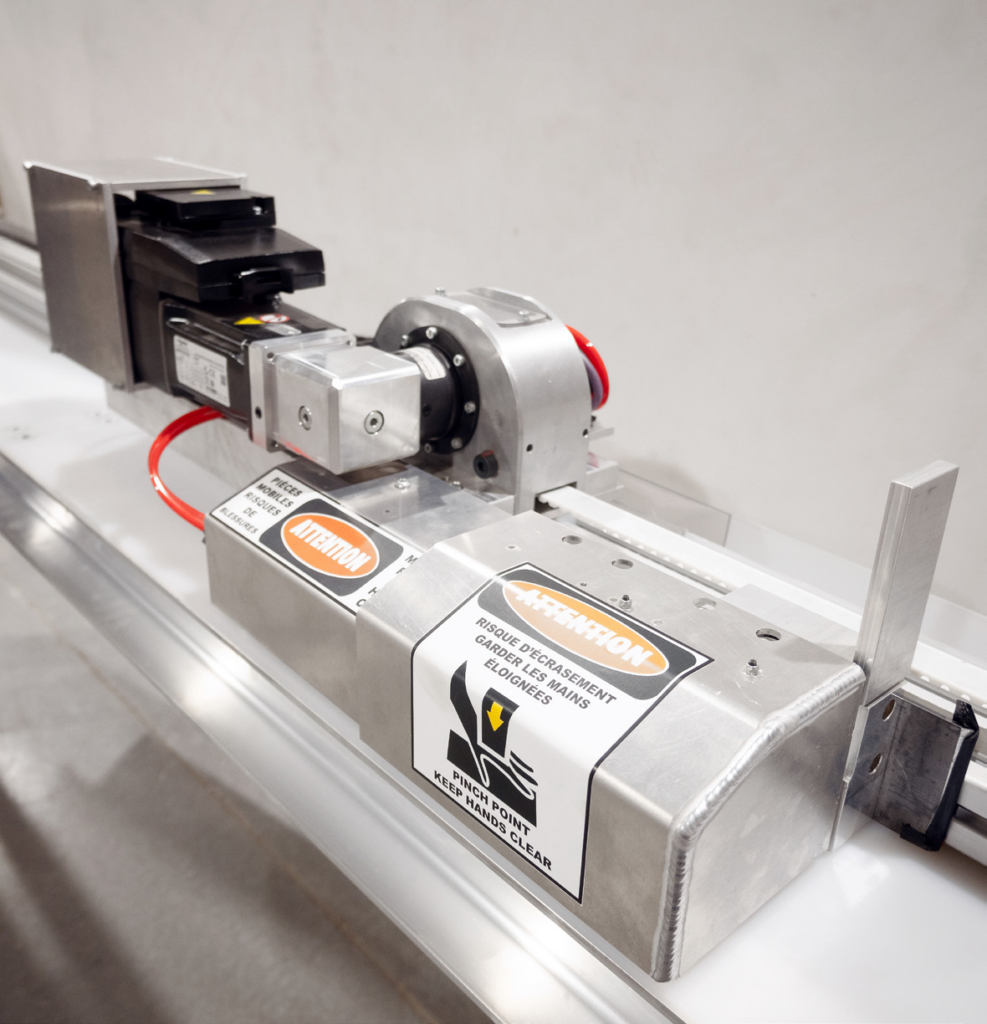

- Two (2) automated stops driven by servomotors pushing the frame gradually as the wall gets build

- Multi-point wood piece retaining and tightening system

- Grippers at top and bottom plate ends to open up the frame when inserting studs and openings

- One-level stud feeder, handling 2×3 to 2×8:

- Store and feed studs required to build the wall, position them in the right order.

- Motorized with an automatic and a forward/reverse step by step manual mode

- Two (2) MAX CN100 pneumatic nailer, or equivalent:

- Handles nail from 2-1/4 to 4in in length; 0.099in to 0.148in diameter

- Hybrid aluminum-steel structure

- Five (5) Schneider-Electric high resolution, high torque, high speed BMi/ILA1series servomotors

- Planetary gearboxes with lifetime lubrication for increased efficiency and minimal maintenance

- Thirty (30) feet conveyor section on the exit side for a larger buffer zone

- 24in Lenovo touchscreen with asi(m) software and ultraintuitive human machine interface

- Electrical control panel meeting cULus standards

- Easy axis by axis calibration

- Manual & automatic modes

- Lifetime access to software updates

SAFETY FEATURES

- Category 3 high end Schneider-Electric XPSMCM controller

- Light bar accross nailing area

- Safe Torque Off (STO)

- Emergency pull cord in front of the stud feeder

- HMI panel e-stops

- Nail guard wraping each nailing area

- Safety zero energy shut-off valve at each nailing gun

- Air shut-down

OPTIONS

- asi(M)O pre-fabricated opening insertion module

- asi(M)2 Squaring-nailing-routing bridge module

- Laser for blocking alignment

- Double-deck automated stud lumber feeder.

- Lot of critical spare parts

- Periodic maintenance program

DOCUMENTATION